Modern spaces demand innovative acoustic solutions that blend performance with aesthetics, transforming how we experience sound in residential and commercial environments. 🎵

The evolution of interior design has brought a renewed focus on minimalism, clean lines, and multifunctional spaces. Yet, one critical element often overlooked is acoustic performance. Traditional bulky sound treatments clash with contemporary aesthetics, creating a dilemma for architects, designers, and property owners who refuse to compromise between form and function.

Enter thin profile acoustic solutions—a game-changing approach that delivers exceptional sound control without sacrificing valuable space or visual appeal. These cutting-edge technologies represent the convergence of advanced materials science, architectural innovation, and acoustic engineering, offering unprecedented flexibility for modern interiors.

🔊 The Challenge of Sound in Contemporary Architecture

Today’s open-plan offices, loft-style apartments, and minimalist homes feature expansive hard surfaces—glass, concrete, polished wood, and metal. While visually stunning, these materials create acoustic nightmares. Sound waves bounce endlessly, creating reverberation, echo, and noise pollution that diminishes comfort, productivity, and wellbeing.

Traditional acoustic treatments typically require significant depth—often four to six inches—to effectively absorb low-frequency sounds. This dimensional requirement conflicts fundamentally with modern design principles that prioritize spatial efficiency and sleek profiles. The challenge becomes even more complex in retrofit situations where structural modifications are impractical or cost-prohibitive.

Furthermore, commercial spaces face additional pressures. Office environments must balance collaboration zones with quiet focus areas. Restaurants need to manage ambient noise levels without appearing institutional. Healthcare facilities require speech privacy while maintaining welcoming atmospheres. Each scenario demands acoustic solutions that work invisibly within the design language.

Understanding Thin Profile Acoustic Technology

Thin profile acoustic solutions leverage advanced material compositions and engineered geometries to achieve remarkable sound absorption in minimal depths—typically ranging from half an inch to two inches. These systems employ several innovative approaches to maximize acoustic performance per millimeter of thickness.

Micro-perforated panels utilize precisely engineered hole patterns that create acoustic impedance, converting sound energy into heat through viscous friction. The perforations are often so small they’re virtually invisible from normal viewing distances, maintaining clean aesthetic lines while delivering broadband absorption.

Resonant membrane absorbers use tensioned materials that vibrate at specific frequencies, effectively targeting problematic bass ranges that typically require substantial depth. By tuning these membranes to problematic frequency bands, designers can address low-frequency issues without bulky bass traps.

Advanced composite materials combine multiple layers with different acoustic properties—such as porous absorbers, reflective barriers, and damping layers—to create synergistic effects that outperform single-material solutions of similar thickness. These engineered assemblies optimize the acoustic impedance gradient for maximum energy dissipation.

🏢 Applications Across Diverse Environments

Corporate and Office Spaces

Modern workplaces have embraced open layouts to encourage collaboration, but this often comes at the cost of acoustic privacy and concentration. Thin profile solutions integrate seamlessly into ceiling systems, partition walls, and even furniture elements. Wall-mounted panels with depths under one inch can reduce reverberation times by fifty percent or more, dramatically improving speech intelligibility and reducing cognitive fatigue.

Many innovative office designs now incorporate acoustic panels as design features rather than afterthoughts. Geometric patterns, custom colors, and integrated lighting transform sound absorption into visual focal points. These dual-purpose installations justify premium positioning in contemporary workspaces where every square foot demands multiple functions.

Residential Applications

Home theaters, music rooms, and open-concept living areas benefit tremendously from thin acoustic treatments that don’t consume precious living space. Ultra-slim panels can be installed behind fabric wall coverings, integrated into millwork, or surface-mounted as artistic elements. Homeowners no longer face the choice between acoustic performance and interior design cohesion.

Urban apartments with concrete construction particularly benefit from these solutions. The hard surfaces that create modern industrial aesthetics also generate harsh acoustic environments. Strategic placement of thin absorbers at reflection points can transform reverberant spaces into comfortable sanctuaries without architectural modifications that might violate lease agreements or condo regulations.

Hospitality and Retail

Restaurants, hotels, and retail environments require carefully calibrated acoustic environments that enhance customer experience without appearing clinical. Thin profile systems install easily during construction or renovation, often integrating with existing ceiling grids or mounting directly to structural elements. The minimal visual impact preserves the intended design aesthetic while controlling noise levels that directly correlate with customer satisfaction scores.

Boutique hotels have embraced acoustic panels as signature design elements—using custom prints, textures, and materials that reinforce brand identity while solving acoustic challenges. A well-designed restaurant can maintain energetic ambiance while ensuring comfortable conversation, a balance that directly impacts patron dwell time and spending.

Material Science Behind the Innovation 🔬

The effectiveness of thin acoustic solutions relies heavily on material engineering breakthroughs developed over recent decades. High-performance acoustic fabrics combine synthetic fibers with specific densities and porosity levels optimized for sound absorption across targeted frequency ranges. These textiles often feature treatments that enhance durability, cleanability, and fire resistance—critical for commercial applications.

Acoustic foams have evolved beyond basic open-cell polyurethane to include melamine, polyimide, and composite formulations with superior performance characteristics. Advanced manufacturing techniques create variable density gradients within single panels, optimizing impedance matching at the air-material interface while maximizing internal energy dissipation.

Recycled and sustainable materials have entered the acoustic marketplace with impressive performance credentials. Compressed recycled polyester panels, agricultural fiber boards, and even mycelium-based absorbers offer environmentally conscious alternatives without compromising acoustic efficacy. These materials appeal to projects pursuing green building certifications and organizations committed to sustainability initiatives.

Aerogel-enhanced composites represent the cutting edge of thin acoustic technology. These materials incorporate one of the lowest-density solids known, creating exceptional porosity in remarkably thin profiles. While currently premium-priced, aerogel composites deliver acoustic performance previously impossible in ultra-slim applications.

Installation Flexibility and Architectural Integration

One of the most significant advantages of thin profile acoustic solutions is installation versatility. Unlike traditional treatments requiring substantial structural support or complex mounting systems, modern thin panels typically install through several straightforward methods suitable for various construction types and project phases.

Magnetic mounting systems allow tool-free installation and easy panel repositioning or replacement. This approach particularly benefits rental properties, temporary installations, and spaces requiring periodic reconfiguration. The non-permanent nature eliminates concerns about wall damage while maintaining secure attachment.

Adhesive-backed panels simplify installation in many scenarios, though proper surface preparation remains critical for long-term performance. High-quality construction adhesives designed specifically for acoustic treatments ensure permanent bonding without off-gassing or material degradation that could compromise acoustic properties over time.

Track and clip systems provide professional-grade mounting with clean finished appearances. These approaches work particularly well for larger installations where individual panel alignment and consistent reveal spacing matter for visual impact. Many systems accommodate slight wall irregularities, essential for older buildings where perfectly flat surfaces don’t exist.

✨ Performance Metrics That Matter

Understanding acoustic performance specifications helps designers and purchasers select appropriate solutions for specific applications. Thin profile products should provide transparent performance data validated through standardized testing protocols.

Noise Reduction Coefficient (NRC) measures sound absorption across speech frequencies, with values ranging from zero (perfect reflection) to one (complete absorption). Quality thin profile panels typically achieve NRC ratings between 0.70 and 0.95, meaning they absorb seventy to ninety-five percent of incident sound energy. These ratings rival or exceed traditional thicker treatments, demonstrating the effectiveness of advanced materials and engineering.

Sound Transmission Class (STC) ratings matter when panels serve as barriers preventing sound transfer between spaces. While absorption and blocking represent different acoustic challenges, some thin profile systems address both through multi-layer construction that absorbs incident sound while reflecting transmitted energy back toward the source.

Frequency-specific absorption data reveals performance across the audio spectrum. Many products excel at mid and high frequencies but struggle with bass absorption—a physics challenge related to wavelength. Evaluating performance curves helps identify solutions appropriate for specific acoustic problems, whether addressing vocal clarity, music reproduction, or mechanical system noise.

Design Customization and Aesthetic Options 🎨

Modern thin acoustic panels transcend purely functional roles to become integral design elements. Manufacturers now offer extensive customization options that empower designers to specify solutions perfectly aligned with project aesthetics and branding requirements.

Digital printing technologies enable photographic reproduction, custom graphics, and artistic expressions on acoustic substrates. Corporate environments can incorporate brand imagery, inspirational graphics, or wayfinding elements into acoustic treatments, maximizing functional density within built environments. The acoustic substrate becomes a canvas for creative expression without compromising sound control objectives.

Fabric covering options span virtually unlimited color palettes, textures, and patterns. Many manufacturers maintain extensive libraries of standard offerings while accommodating custom material specifications. This flexibility allows acoustic treatments to blend seamlessly into existing color schemes or serve as accent elements that define spatial character.

Three-dimensional forming and laser cutting create geometric patterns, organic shapes, and architectural relief that add visual interest and tactile dimension. These techniques transform flat acoustic panels into sculptural elements that cast shadows, create depth, and engage viewers beyond simple color and pattern. The dimensional manipulation can also enhance acoustic performance through increased surface area and edge diffraction effects.

Economic Considerations and Value Proposition 💰

While thin profile acoustic solutions may carry higher per-square-foot costs than basic foam panels or fiberglass batts, comprehensive project analysis typically reveals strong value propositions across multiple dimensions.

Installation efficiency reduces labor costs significantly. Thin panels install faster than bulky alternatives, particularly in retrofit scenarios where structural modifications would otherwise be necessary. The reduced installation time translates directly to lower labor expenses and shortened project timelines—critical factors for commercial projects where delays cost money and interrupt operations.

Space efficiency delivers tangible economic value in expensive real estate markets. Reclaiming even two inches of ceiling height or wall projection per treated surface adds up across large projects. In commercial spaces where lease rates are calculated per square foot, this spatial efficiency directly impacts occupancy costs over facility lifecycles.

Lifecycle performance and durability factor into total cost of ownership calculations. Quality thin profile products maintain acoustic performance indefinitely with minimal maintenance. Fabrics resist sagging, materials don’t degrade or shed particles, and installations remain dimensionally stable across temperature and humidity variations. This longevity avoids replacement costs and disruptions associated with lower-quality alternatives.

Sustainability and Environmental Impact 🌱

Building sector sustainability initiatives increasingly scrutinize material selections, pushing acoustic solutions toward reduced environmental footprints. Thin profile technologies align well with green building objectives through multiple pathways.

Material efficiency inherently reduces resource consumption. Achieving equivalent acoustic performance with less material means lower embodied energy, reduced extraction impacts, and decreased transportation emissions. Lightweight products ship more efficiently, further minimizing carbon footprints across supply chains.

Recycled content options address circular economy principles. Many manufacturers incorporate substantial post-consumer or post-industrial recycled materials into acoustic products without performance compromises. These specifications help projects achieve LEED credits, BREEAM ratings, and other sustainability certifications while delivering required acoustic performance.

Indoor air quality considerations favor low-VOC formulations now standard in quality acoustic products. Adhesives, binders, and coatings employ water-based chemistries or zero-emission alternatives that contribute to healthy interior environments. This characteristic particularly matters in schools, healthcare facilities, and other sensitive applications where occupant wellbeing demands priority attention.

Future Trajectories in Acoustic Innovation 🚀

The acoustic solutions industry continues evolving rapidly, driven by material science advances, computational design tools, and changing architectural paradigms. Several emerging trends promise even more impressive capabilities in ultra-thin formats.

Active noise control integration could combine passive absorption with electronic cancellation technologies. Imagine wall panels that not only absorb sound but also emit precisely timed anti-phase signals to cancel specific problematic frequencies. While current active systems remain relatively bulky and expensive, miniaturization trends suggest eventual integration into architectural finishes.

Smart materials with tunable acoustic properties may enable dynamic spaces that adjust absorption characteristics based on occupancy, activity type, or time of day. Electroactive polymers and phase-change materials under development could transform static acoustic treatments into responsive systems optimized for changing conditions.

Biomimetic designs inspired by natural sound control mechanisms offer promising research directions. Studying how owl feathers enable silent flight or how specific plant structures dissipate wind noise may unlock novel geometric or material approaches applicable to architectural acoustics.

Specifying and Implementing Solutions Successfully

Achieving optimal results with thin profile acoustic solutions requires thoughtful specification processes that align products with specific project requirements and constraints. Several key considerations guide successful implementations.

Acoustic analysis should precede product selection. Professional acousticians can model existing conditions, predict treatment effectiveness, and recommend strategic placement that maximizes performance while minimizing material quantities. This expertise-driven approach prevents over-treatment or under-specification that wastes resources or fails to achieve objectives.

Mock-ups and samples prove invaluable for evaluating aesthetic integration and performance characteristics. Viewing small samples under showroom lighting rarely replicates how materials appear in actual project contexts. Full-scale mock-ups reveal texture, color relationships, and installation details that inform final specifications and prevent costly disappointments.

Coordination across trades ensures acoustic treatments integrate properly with lighting, HVAC, and other building systems. Early collaboration prevents conflicts, identifies value engineering opportunities, and streamlines installation sequences. This coordination becomes particularly critical in tight ceiling plenums or complex wall assemblies where multiple systems compete for limited space.

Transforming Spaces Through Sound Management 🎯

The impact of proper acoustic treatment extends far beyond technical performance metrics. Spaces with controlled reverberation and managed noise levels fundamentally feel different—more comfortable, more productive, more conducive to their intended purposes. This qualitative transformation represents the ultimate value proposition of thin profile acoustic solutions.

Workplace productivity research consistently demonstrates correlations between acoustic comfort and employee performance. Reducing distracting noise and improving speech intelligibility directly impacts concentration, collaboration effectiveness, and job satisfaction. Organizations investing in acoustic optimization report measurable returns through reduced sick days, improved retention, and enhanced output.

Educational environments benefit substantially from proper acoustic treatment. Speech intelligibility determines how effectively students receive instruction, particularly for younger learners and non-native speakers. Classroom acoustics meeting established standards correlate with better academic outcomes, justifying acoustic investments as educational infrastructure rather than cosmetic upgrades.

Healthcare facilities recognize that acoustic comfort influences patient recovery, stress levels, and satisfaction scores. Excessive noise interferes with sleep, elevates blood pressure, and contributes to medical errors. Thin profile solutions enable acoustic improvements in existing facilities without major renovations that would disrupt patient care operations.

The revolution in thin profile acoustic solutions represents more than technological advancement—it reflects evolving understanding of how sound shapes human experience within built environments. As awareness grows regarding acoustic quality’s impact on wellbeing, productivity, and satisfaction, demand intensifies for solutions that deliver performance without aesthetic or spatial compromises. Modern thin profile technologies answer this demand elegantly, proving that exceptional acoustic control and contemporary design sensibility can coexist beautifully within the same millimeter-thin installation. The future of architectural acoustics lies not in bulky treatments hidden from view, but in sophisticated solutions that enhance both sonic and visual dimensions of the spaces we inhabit.

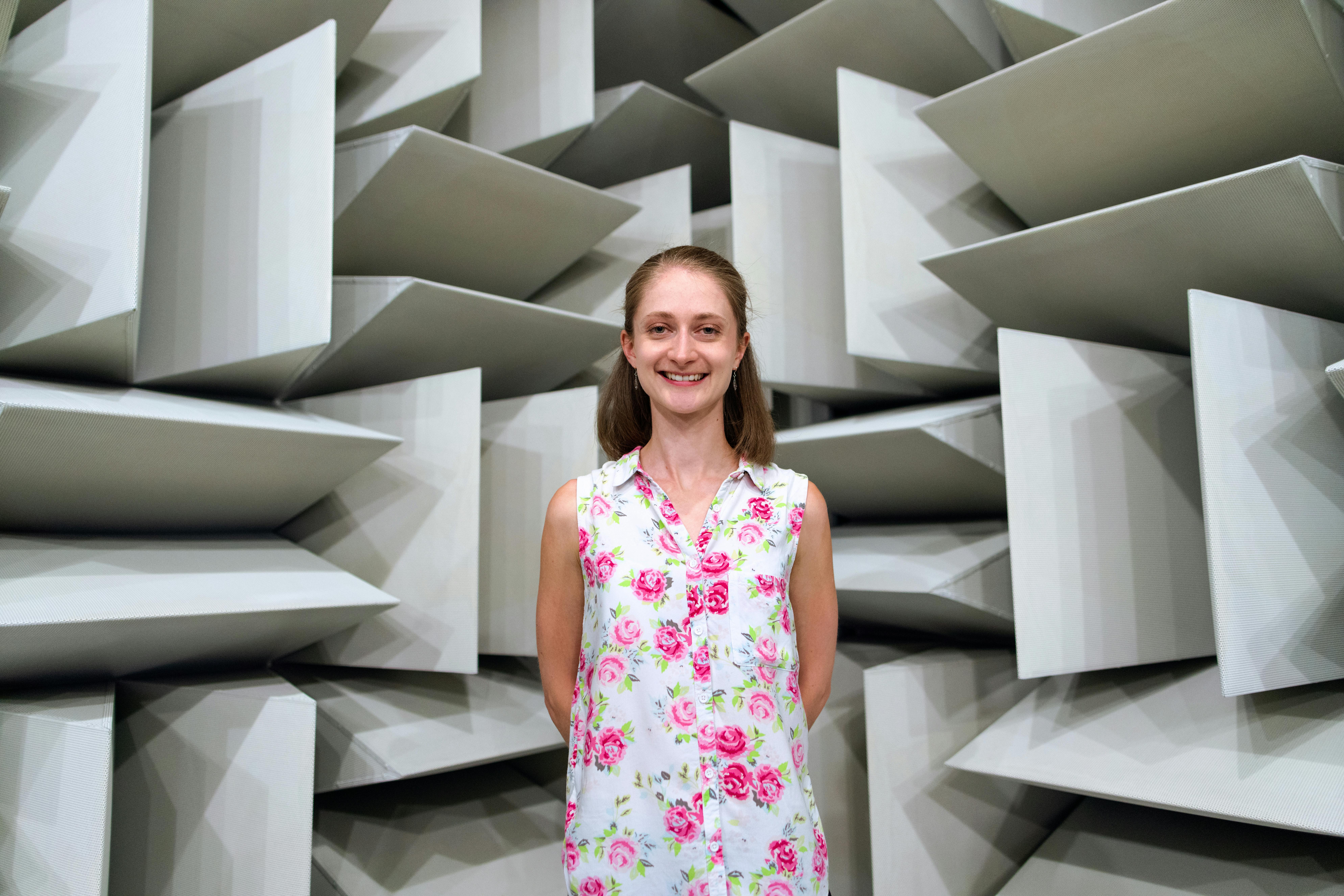

Toni Santos is an acoustic engineer and soundproofing specialist focused on advanced noise-reduction systems, silent workspace optimization, and structural acoustics for residential and commercial environments. Through an interdisciplinary and performance-focused lens, Toni investigates how modern living spaces can be transformed into acoustically controlled sanctuaries — across apartments, home offices, and existing buildings. His work is grounded in a fascination with sound not only as vibration, but as a controllable element of spatial comfort. From advanced acoustic material applications to smart noise-cancellation and structural soundproofing techniques, Toni uncovers the technical and practical tools through which environments achieve measurable noise isolation and auditory clarity. With a background in architectural acoustics and building retrofit methodology, Toni blends performance analysis with applied engineering to reveal how spaces can be optimized to reduce disturbance, enhance focus, and preserve acoustic privacy. As the creative mind behind cadangx.com, Toni curates detailed soundproofing guides, room acoustics assessments, and material-based solutions that empower homeowners, designers, and builders to reclaim control over their acoustic environments. His work is a tribute to: The precise application of Advanced Acoustic Materials for Apartments The strategic layout of Silent Home Office Design and Optimization The technological integration of Smart Noise-Cancellation Room Systems The retrofit-focused methods of Structural Soundproofing for Existing Buildings Whether you're a homeowner, acoustic consultant, or builder seeking effective noise control solutions, Toni invites you to explore the proven strategies of sound isolation — one wall, one panel, one quiet room at a time.